Rotary Laser Level

Related Products

-

Self-Leveling Laser Level

-

Green Beam Laser Level

-

Rotary Laser Level

-

Reticle Line Laser Level

-

Green beam 12 Lines Laser Level

-

Construction Laser Level

-

Multifunctional Laser Line Projector

-

Digital Laser Line Projector

-

Industrial Laser Line Projector

-

Handheld laser line Projector

-

Laser Line Projector Lifting Tripod

-

Laser Line Projector Heavy Duty Lifting Tripod

Who are we?

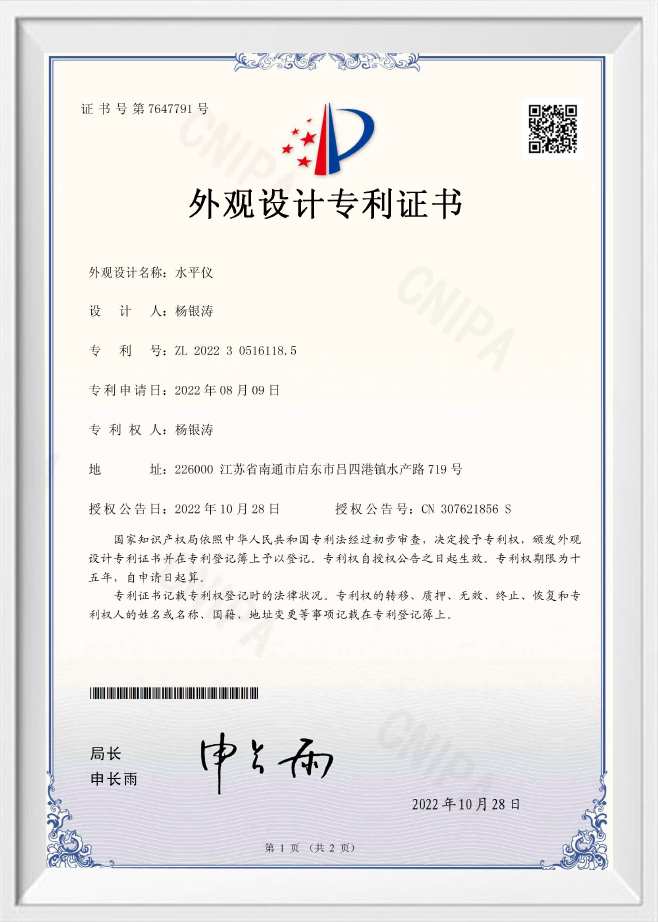

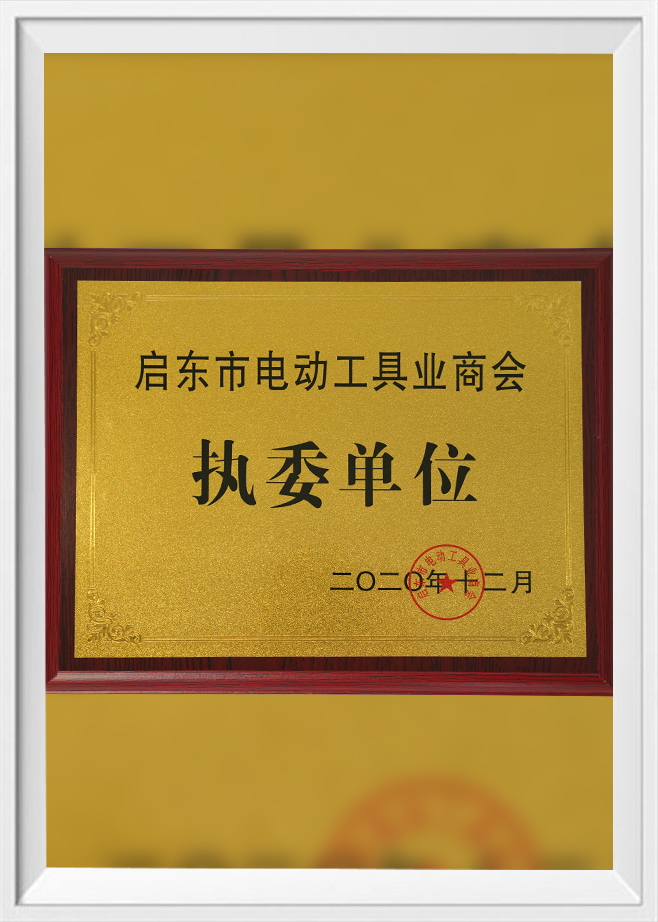

Qidong Zongheng Optoelectronics Technology Co., Ltd. is professional China Rotary Laser Level Manufacturers and Wholesale Rotating Laser Level Suppliers. The company was founded in 2010 and is located in the famous capital of power tools - Lusi Marine Economic Development Zone, Qidong City, Jiangsu Province. The company has a complete industrial production base, modern standard workshops and multiple professional production lines. The company has introduced high-end laser technology and has a group of innovative and enterprising R&D backbones and a professional and efficient manufacturing team.

Over the years, Zongheng Company has regarded innovation as an inexhaustible driving force and relied on technological innovation to promote the continuous upgrading of Zongheng tools. At the beginning of the product design, the advantages and disadvantages of similar products on the market were collected for comparative analysis, and it was widely adopted by operators operating under various harsh conditions. reasonable suggestions and needs, strive to reduce the user's working physical strength and working time. The design advantages combined with Zongheng's rigorous work attitude and strict quality control system ensure that Zongheng's products can operate efficiently under harsh conditions and still maintain durability. service life.

-

Annual Production Equipment

0+ -

Development Period

0+ -

Industry Development Years

0+ -

Plant Area

0㎡+

From The Blog

Provide you with the latest enterprise and industry news

-

How to calibrate the 4D green crosshair laser projector to ensure its projection accuracy?

1、 Preparation stageSelect calibration environment:Choosing a suitable calibration environment is crucial before calibrating the 4D green crosshair la...

Read More >>> 2024-10-28 -

How to ensure the lifting stability of Laser Line Projector Lifting Tripod?

1、 Tripod structure designMaterial selection:The selection of materials is crucial in ensuring the stability of the Laser Line Projector Lifting Tripo...

Read More >>> 2024-10-21 -

How to calibrate Reticle Line Laser Level correctly to ensure accuracy?

1、 Prepare calibration tools and environmentIt is crucial to have the necessary calibration tools before preparing to calibrate the Reticle Line Laser...

Read More >>> 2024-10-14 -

How Do Environmental Factors Affect the Performance of a 5 Lines Laser Level?

1. TemperatureTemperature has a profound impact on the performance of a 5 lines laser level. Each laser level is designed to operate within a specific...

Read More >>> 2024-10-07

Industry Knowledge Extension

How does a Rotary Laser Level work?

What factors influence the accuracy of a Rotary Laser Level?

Contact Us

-

Email: [email protected]

-

Telephone: +86-513-83449118

-

Fax: +86-513-83449118

-

Phone: +86-18962839249

English

English русский

русский